Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

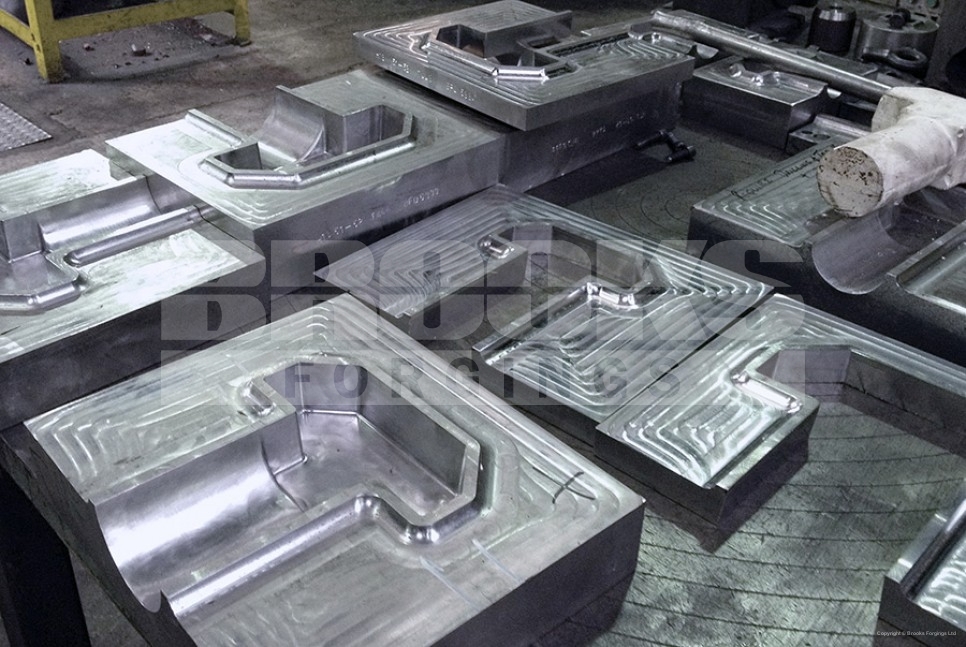

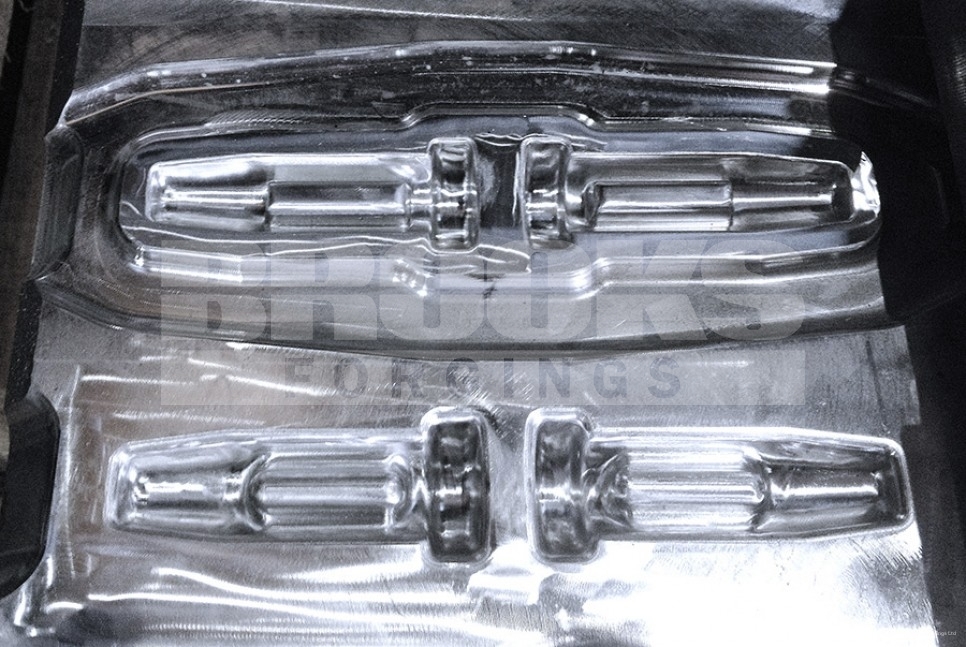

Rapid in-house production of forging dies & tooling to guarantee quality and improve lead time.

Our in-house technical staff, tool room, and die-sinking capability are an essential part of our manufacturing operation, giving us complete control and flexibility throughout production.

Our fully integrated CAD/CAM package is wirelessly linked to high-speed machining centers for a rapid die sinking turnaround.

By keeping these processes in-house, we can utilize the expertise of our technical staff who are familiar with our processes and equipment. This guarantees that we produce the correct tooling for production and the end component is manufactured in the most efficient and economical way possible.

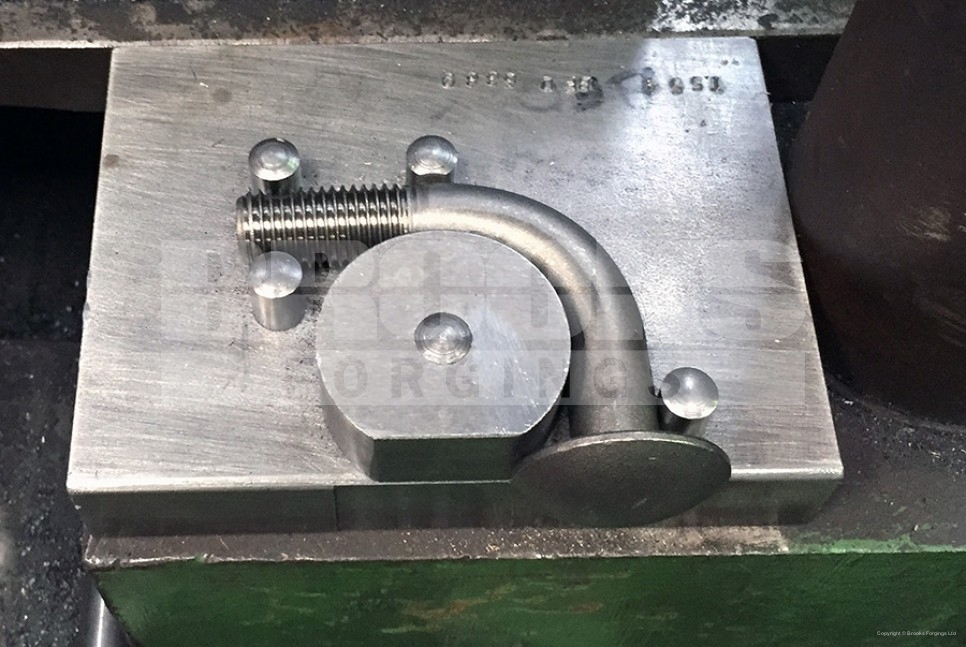

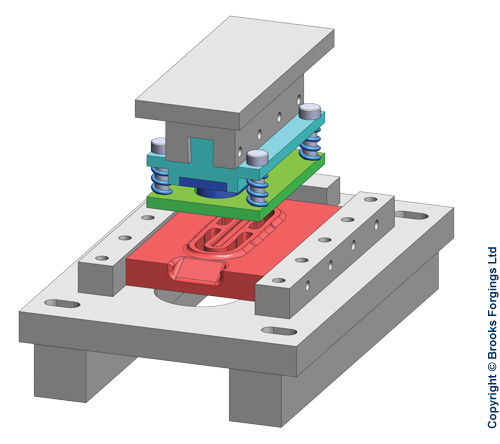

Jigs & fixtures for production and inspection ensures consistent quality

Jigs & fixtures for production and inspection ensures consistent quality

Our in-house tool room plays a vital part in assisting our production and quality control department.

Component inspection jigs can be produced ensuring 100% dimensional checks throughout production.

These can be in the form of complex GO and NO-GO gauges or as simple as a pin-based jig.

Some processes require specially designed fixtures, such as machining and robot welding.

These fixtures are designed to maximise turnaround and the footprint available for each sequence rotation.