Project in mind?

Please call us now on

+44 (0)1384 563356

Email your enquiry to

sales@brooksforgings.co.uk

Capacity of 6mm up to 60mm in Square or Round solid section.

No foreign weld material is used.

Heat treatable after welding.

The main advantages of Flash Butt welding are the speed and the overall strength of the process, there is no foreign weld material used meaning the product can be heat treated afterward further increasing tensile strength.

This process is regularly used where high strength is required, typically lifting links and chains.

The Flash Butt Welding Process

A process where the surfaces of the workpieces are positioned end to end and are then electronically charged, producing an electric arc that melts and welds the ends of the segments.

Flash Butt Welding is typically divided into 3 stages:

• Preheating

• Flashing

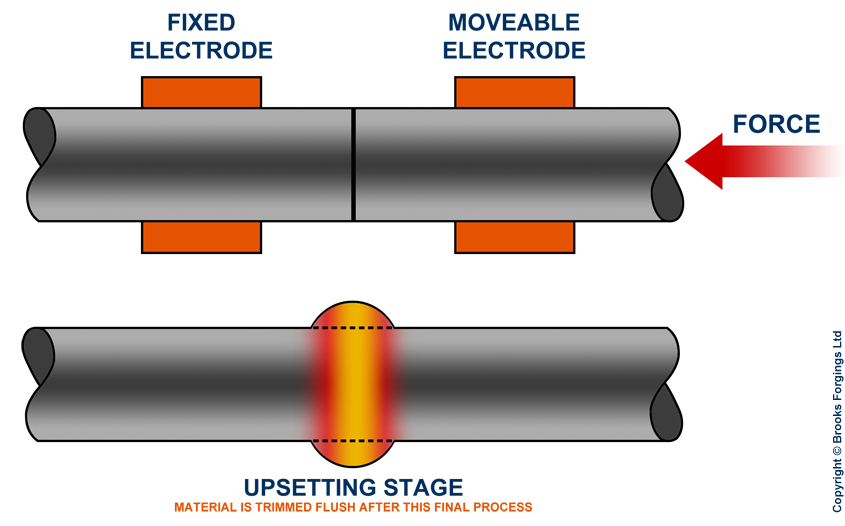

• Upsetting

Preheating is carried out under low welding pressure. Once the welding joint is heated, flashing commences.

The joint surface material is burnt off, resulting in an even surface. After arriving at pre-set flashing loss, upsetting commences, resulting in an irregular "fin" on the surface of the upset metal consisting of molten and oxidized material.

Automated Flash Butt Welding

We have recently commissioned a fully automated flash butt welding machine at our manufacturing facility

The key advantages are the programmable and repeatability of the weld procedure that allows an identical weld to be performed on every component. Job-specific data can be saved in the archive and then recalled at a later date offering full traceability for our Quality Department. This also removes any operator error, which is another major advantage over conventional manual flash butt welding machines, as there is a looming skill gap in British manufacturing.

The guarding system has been designed to accommodate material up to 12 meters in length. This is particularly useful for components that are used in tensioning or lifting applications as forged ends can be produced more economically in shorter lengths and then flash butt welded to the same plain bar stock from the original cast.

Our automated machine can weld up to 60mm diameter or square material but can also accommodate flat sections.

On-site Strength and Ductility Testing

Our flash butt welding service is supported by various on-site testing procedures that include:

Bending, to evaluate ductility at the weld area.

Destructive / Tensile Testing, to evaluate working load by using our 50 Tonne Mayes testing machine.

With the installation of a fully automated flash butt welding process, we are able to conduct internal testing to establish the correct calibration setting of the machine. Pre-heat, pressure and timing all impact the welding process and this varies depending on the material grade and diameter/section used. Once the test data is approved, the setting can be stored and recalled at any time to make it a fully repeatable process.