We are able to produce a wide range of forged, machined, and fabricated components to customer requirements.

Standard or fully bespoke, we can assist.

Our diversity enables us to offer our customers unrivaled service and a single source of procurement for their individual requirements.

Below are some of the product ranges we can offer. Do contact us today with your specific requirements.

-

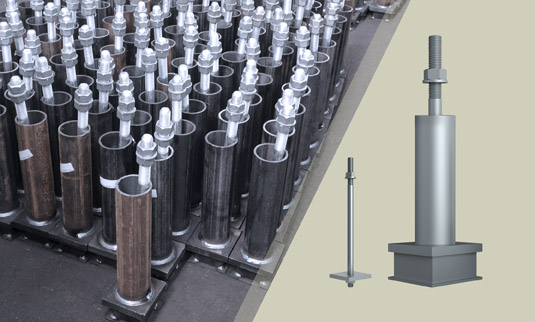

Foundation Bolts & Holding Down Bolts

-

Hammerhead T Bolts

-

Special Fasteners

-

Eye Bolts & Lifting Eyes

-

Shackles

-

U-Bolts, J-Bolts, L-Bolts, N-Bolts, V-Bolts

-

Galvanised Fasteners

-

Foundation Assemblies

-

Forged Blanks & Near Net Shapes

-

Lifting Gear & Tackle

-

Torsion Bars

-

Tension System Components

-

Brackets

-

Liner, Crusher, and Wedge Bolts

-

Punching Shear Reinforcement Systems

-

Overhead Line Fittings

-

Hand Tools

-

Mooring Rings

-

Skip & Container Components

-

Tent Pegs & Marquee Stakes

-

Decorative Ironwork